How to make a good quality feeder cable?

The production of an antenna involves the assembly and welding of various components. Among these steps, the inspection of the feeder cable stands out as the foremost and crucial stage. The quality of the feeder cable sets the foundation for a high-quality antenna.

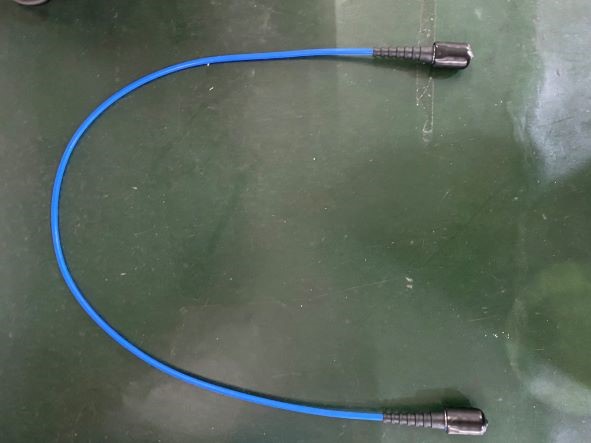

Let’s delve into the process and functionality of a certified feeder cable.

To initiate the process, we begin by inputting the desired length and quantity of cables into the multi-function cable stripper. Once configured, the wire stripper commences the precise cutting of the cables from the bundle.

Moving on to the second step, we insert the cut cable into the semi-automatic wire stripping machine. Here, we input the specific size and style of wire stripping required for the cable, initiating the stripping process.

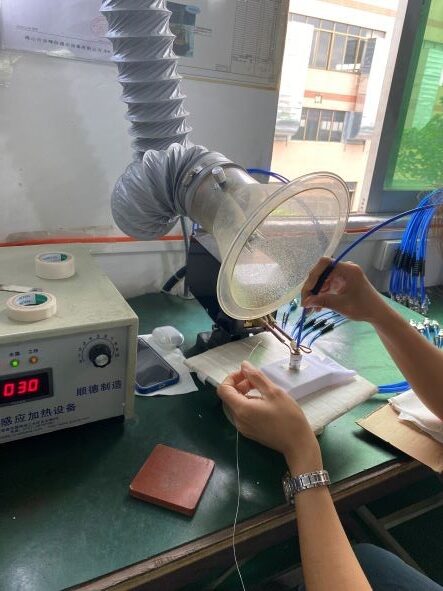

Proceeding to the third phase, the cable sleeve is stripped, and the injection sleeve is fitted. This protective measure shields the wire assembly, ensuring durability and preventing breakage.

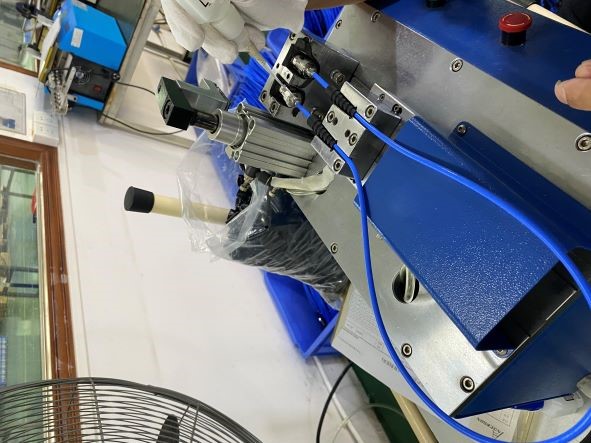

In the fourth stage, the cable encased in the injection molding sleeve is introduced into the automated soldering machine for needle welding. Specifications, such as solder length and tin wire temperature, are inputted. It’s essential to ensure precise soldering without the occurrence of any soldering needle exposure or faulty welding during this process.

Moving forward to the fifth phase, we again employ a fully automated soldering machine. However, in this instance, it’s dedicated to welding the cable joint. Following the pin welding, the joint is subjected to the same meticulous welding procedure, ensuring the absence of any virtual welding or leakage.

Progressing to the sixth step, the soldered connector cable is placed onto the intermodular for comprehensive testing. This evaluation encompasses both low-frequency and high-frequency assessments, tailored to adhere to the specifications outlined in the order requirements.

Proceeding to the seventh stage, we conduct thorough evaluations of the low-frequency and high-frequency cables, including a standing wave test performed on the network analyzer. During this test, it’s crucial to ensure that the standing wave of the cable does not exceed 1.25.

The concluding step entails affixing the injection sleeve securely with adhesive. This steadfast attachment of the injection sleeve serves as enhanced protection against potential cable damage. With these steps completed, you have a comprehensive and resilient cable solution.

A fully functional and stable feeder forms the foundational cornerstone of antenna construction.